Sponsored news from Deceuninck:

Dekko turned to Deceuninck Aluminium to manufacture products that will sit alongside its high-end Räum range of windows and doors when the fabricator reviewed its options in 2022.

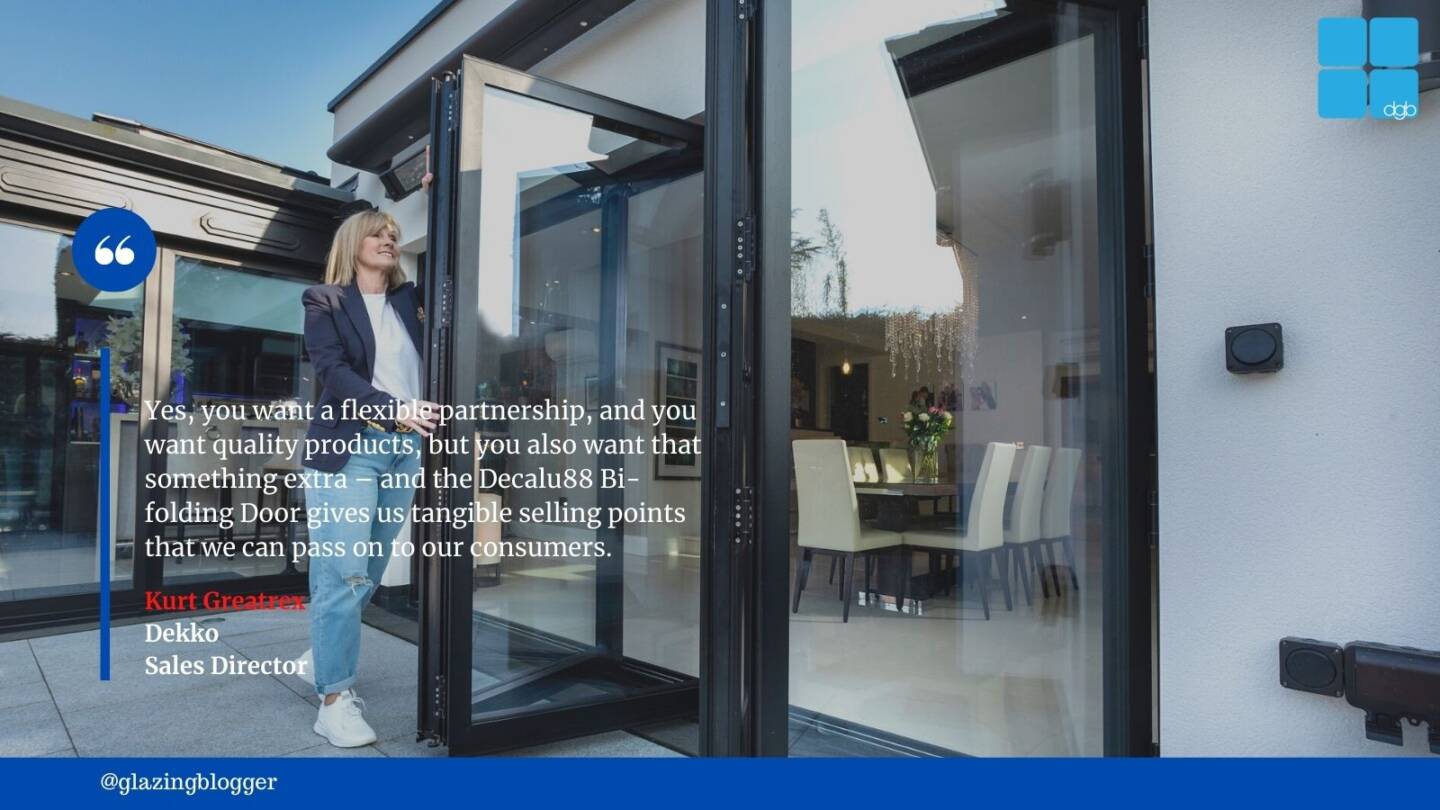

“There are many things to consider when you choose a supplier for your flagship brand,” explained Dekko’s Sales Director Kurt Greatrex. “Yes, you want a flexible partnership, and you want quality products, but you also want that something extra – and the Decalu88 Bi-folding Door gives us tangible selling points that we can pass on to our consumers.”

Kurt explained that the product’s energy efficiency credentials – U-values as low as 0.68W/m2k triple-glazed or 1.4W/m2k double-glazed making it Part L and Future Homes ready – are vital for any business looking to future-proof themselves against the introduction of the Future Homes Standard in 2025.

But the fact that the Decalu88 Bi-folding Door is available in any single or dual RAL colour option – textured and metallic finishes – and is Marine Grade as standard, helps Dekko position itself as a modern forward-thinking company as homeowners and specifiers choose coloured products in greater numbers than ever before.

Already a fabricator of Deceuninck PVC-U profile, Dekko was familiar with the brand and recognised the benefits offering Deceuninck across the board would bring. Despite this, Kurt explained that the Lancashire-based fabricator was only going to introduce the Decalu88 B-Folding Door and Entrance Door to its range.

“That was until we got a request from a customer to fabricate the Decalu163 Lift-and-Slide Door to a £1.1m 12-month project in London,” Kurt said. “It was one of those rare occasions where the project had been up-specced to aluminium from PVC-U, and it would have been too good an opportunity to miss.”

Also, ultra-energy-efficient with U-values of as low as 0.8W/m2k triple-glazed or 1.3W/m2k double-glazed, making it Part L and Future Homes ready, the Decalu163 Lift-and-Slide Door combines minimalist sightlines with effortless operation despite accommodating individual sash weights of up to 400kg.

“But the request came in at the same time we were setting up to start manufacturing the Decalu88 Bi-Fold Door and the Decalu88 Entrance Door, so we had to work out if we could take on the Lift-and-Slide Door as well,” Kurt continued.

“As it turned out, thanks to the modular Decalu system, we only needed one extra punch tool to expand our production capability – everything else remained the same.”

Kurt explained that Dekko also has its eyes on the new Decalu88 Flush Casement Window from Deceuninck Aluminium because it will be attractive to both domestic and commercial customers – especially if they were buying other products from the range.

“People will want the same flush sightlines across all elements of their project,” he said. “But our customers will benefit in other ways – beyond winning more work.

“The feedback we have received from fitters is that the Decalu products are easy to install and easy to glaze. The system is much more straightforward when compared to other aluminium systems.

“Take the bead for example – it is the same across the range. This not only means that you have a uniform appearance across all glazing elements, but you don’t have multiple beads on site. This means lower stockholding for fitters, but they don’t run the risk of having the wrong bead on site, which means having to return at a later date with the right bead, saving time and money.

“And there are significant benefits for us as a fabricator, especially when it comes to stockholding. On a Decalu system, I only need to stock four separate products. For a similar style aluminium system, that number is ten. That complexity takes up more space, requires more detailed logistics, and ties up my money in stock – up to 200% more.”

Kurt said the immediate benefit for Dekko was improved cash flow, which is a key strength to have as the market starts to cool.

“This attention to detail – the modular system and pre-gasketed beads – also improves my relationship with my customers,” he said. “They are much quicker on site, they are less likely to leave a job unfinished while they wait for the right parts to turn up, and they get paid quicker. Which is what we all want!”

For more information call 01249 816 969, email deceuninck.ltd@deceuninck.com or visit www.deceuninck.co.uk

To get weekly updates from DGB sent to your inbox, enter your email address in the space below to subscribe:

By subscribing you agree to DGB sending you weekly email updates with all published content on this website, as well as any major updates to the services being run on DGB. Your data is never passed on to third parties or used by external advertising companies. Your data is protected and stored on secure servers.